Certificates

Kekkilä-BVB introduces sustainability roadmap for 2030

KEKKILÄ-BVB PRESS RELEASE 28.1.2020

Kekkilä-BVB has set demanding targets to become a net positive company by 2030, guided by our sustainability roadmap with eight concrete targets. One example of Kekkilä-BVB´s sustainability actions is to launch products containing sphagnum moss for professional growers and retail customers.

“It is quite natural for horticultural companies to talk about sustainability, since we are all contributing in making the world a greener place one way or the other. But that is not enough. It´s all about how we do it”, says Juha Mäkinen, CEO of Kekkilä-BVB.

Kekkilä-BVB became the leading horticultural company in Europe after Finnish Kekkilä and Dutch BVB Substrates joined forces.

“With big size comes also big responsibility. It is our obligation to promote biodiversity and to participate in preventing the effects of climate change. We have taken the stand to be a promoter for sustainable horticultural business and to enable our customers to meet their sustainability goals”, Mäkinen says.

Sustainability roadmap steers actions

Kekkilä-BVB´s sustainability work is guided by a sustainability roadmap. It consists of four focus areas with measurable targets. These focus areas are related to the wellbeing of people in the value chain, creating sustainable new innovations for food production and living, promoting circular economy and enhancing biodiversity.

“Concreteness is very much needed in sustainability work. This was a very clear message both from our customers and personnel when we made our sustainability roadmap. One way to add concreteness is to openly measure the negative and positive impact. This is why we are participating in Growing Media Europe´s work in calculating LCA (Life Cycle Assessment) for different growing media materials. This builds the base for the sustainability standard for the European growing media industry”, concludes Mäkinen.

From talk to action

An example of Kekkilä-BVB´s sustainability driven business approach is the launch of substrates containing sphagnum moss at the global horticultural fair, IPM Essen.

Sphagnum moss grows on top of the peat bogs and has not started to decompose like peat. As a living material it regrows relatively quick. Less water is needed for crops grown with sphagnum moss, since it has a large water holding capacity. Tests have also shown excellent growth results.

“To ensure our customers’ success and that the growth results are optimal, we have done extensive tests before launching our products with sphagnum moss. We see that as part of our responsibility.”, adds Mäkinen.

Since sphagnum moss is a novelty raw material and acts differently than peat, it is not yet RHP (quality mark for substrates) certified. Kekkilä-BVB is co-operating with RHP to have it certified according to RHP´s standards.

Read more about Kekkilä-BVB´s concrete sustainability cases here: kekkila-bvb.com/sustainability

Contact:

Juha Mäkinen, CEO, Kekkilä-BVB: juha.makinen@kekkila-bvb.com, tel. +358 40 046 4549

Nina Kinnunen, Director, Sustainability, Brand and Communications: nina.kinnunen@kekkila-bvb.com, tel. +358407775333

Retail

Introducing a virtual festival and discussion forum for the green industry to drive more sustainable growing – Grow Festival

Press release 12.1.2021

Online festival Grow21 will be organised online on the 9th-11th of February, 2021

The new virtual event for the horticulture, gardening and landscaping industry is powered by Kekkilä-BVB, the European leader in horticulture. We invite all to come together to discuss and develop the green industry towards more sustainable growing.

During this three-day festival, we invite you to join our extended industrial community to gain inspiration, learn about new trends, share experiences and hear esteemed keynotes and panels. In addition you will have the opportunity to join in-depth sessions and local webinars with the green industry stake holders. Together we can plant the seeds for sustainable future!

“Many horticulture and gardening industry events have been cancelled or postponed due to Covid 19. We want to bring light and inspiration to our current restricted reality. We have invited over 20 experts from different organisations in Europe to share their knowledge and insight to create an interesting and inspiring agenda. We hope that the participants will benefit from these presentations and webinars.” says Juha Mäkinen, CEO of Kekkilä-BVB and the Chairman of Growing Media Europe association.

The agenda of the first online Grow Festival will include:

Keynotes:

- Urban green environments

- Consumers after Covid 19

- Gardening trends in Europe

- Optimizing shopper marketing

- Preserving biodiversity

- Future of sustainable growing

Panel discussions and interviews:

- Shopper behaviour in the new normal

- Climate change driving the change in the food industry

- Responsibly produced peat (RPP)

Local expert webinars on various topics

The day 1 focuses on biodiversity in urban environment.

Securing biodiversity, building green areas and recycling are more important topics than ever to take into account when designing the future urban areas. We will discuss the future green cities, the friendly micorbes that ensure the biodiveristy under ground and within the soil. Roof gardens will be a big add-on in securing the biodiversity above the ground. We will not only see the traditional meadows on the ground but more and more green patches attached to the houses and other buildings on the roofs and walls as well as the river banks.

The key focus of the day 2 will be on the consumers.

Consumer needs and behaviour is changing more rapidly than ever. What are Covid-19 impacts on consumers’ behaviour, what kind of gardening trends will there be in the near future and how does gardening support us all in the new normal, how do the shoppers behave both in the physical as well as virtual shops now and in the future – these questions and many more will be answered during the day 2.

The Day 3 will be about the sustainable professional growing in the future.

What kind of changes are there to be expected after Covid-19 in this industry? How the future professional growing and growing media will look like and how to ensure the growing media for the future food production for the enlarging population? These questions and many more will be answered. And finally we will dig in to the changes driven by the climate change on the food production, distribution and consumption.

Registrations

The registrations opens on January 12 at www.Kekkila-BVB.com/GrowFestival

Registration per the main session of the day and separately for the local webinars.

The festival is free of charge.

More information:

Nina Kinnunen, Director, Sustainability, Brand and Communications

nina.kinnunen@kekkila-bvb.com, +358407775333

Anna-Marja Vainio, Senior Manager, Communications

anna-marja.vainio@kekkila-bvb.com, +358505531913

Alternative casings and a sustainable mushroom industry

Mushrooms are a low-impact food. As vertical farms, their land footprint is small, and energy and water inputs into mushroom crops are much lower than comparable foods. Consequently, mushrooms have an excellent CO2eq rating. This ‘green’ image, coupled with great taste and an ever-growing list of health benefits, weaves a sweet narrative of mushrooms as a sustainable food source for a growing world population.

There is just one little snag:

Casing, or more specifically, peat casing.

Peat extraction, its history, ecology, the debate around sustainability, and its application in the horticultural industry could fill pages. What is relevant is that the UK, Ireland and Germany, major peat suppliers, are considering phasing out peat extraction. And although there is currently sufficient supply of peat for the horticultural industry, sustainable alternatives are needed to future proof the mushroom industry.

As a country without peat extraction, Australian growers have relied on expensive imports from Europe. Development of an alternative casing from local materials would potentially save cost, avoid shipping delays, and enhance the sustainability of the mushroom industry.

Presentations at the AMGA conference from Folkert Moll (Kekkilä BVB) and Dr Ralph Noble (Microbiotech Ltd) showcased the latest developments in Europe, where much of his research is occurring.

Key sustainability trends impacting the industry

The mushroom industry is not immune to global events, whether they be social, economic, or environmental. Wholesalers and retailers are acutely aware of the impact of sustainability on brand values and scrutinise supply chains accordingly.

Provenance claims, whether a diamond, a bottle of wine, or a mushroom, no longer start and end with location; the full supply chain is part of the story, including any raw materials, used in production.

So where do you start? Folkert Moll, the sustainability manager at Kekkilä BVB, brought all this it into clear context for the mushroom industry. To navigate a path to sustainable casing, his company is looking to the UN Sustainable Development Goals1 as a guide. Six key development goals impact the mushroom industry particularly, namely urbanisation, climate destabilisation, ecosystem decline, food crisis, inequality, and resource scarcity.

So where do you start? Folkert Moll, the sustainability manager at Kekkilä BVB, brought all this it into clear context for the mushroom industry. To navigate a path to sustainable casing, his company is looking to the UN Sustainable Development Goals1 as a guide. Six key development goals impact the mushroom industry particularly, namely urbanisation, climate destabilisation, ecosystem decline, food crisis, inequality, and resource scarcity.

Resource scarcity is the immediate focus, including:

- Availability of local and circular raw materials

- Competition with other substrates and industries

- Quality of available raw materials and processing needs

- Upscaling from research to commercial application

So, what makes a good casing material?

The holy grail of an alternative casing, simply put, is a material that is as good as peat but with a lower environmental footprint. Each raw material has pros and cons, and chemical, physical, and biological properties need to be well understood. Further, these properties can change when materials are mixed.

Specific characteristics include:

- high-water holding capacity

- low salt content

- hostile to moulds

- low cost

- readily and reliably available locally

- does not stick to mushrooms

- no pathogens or contaminants

- does not attract flies

New solutions

According to Wageningen University in the Netherlands, the volume of growing media will need to increase by 332% over the next 30 years to meet the food demands of a growing world population.

By 2050 the amount of new raw materials (not yet commercially in use) has to equal the total amount of raw materials currently used for growing media. This already huge challenge is compounded by the competition for resources from other industries.

Demand for peat will likely double, although this largely depends on the political trade-off between the role of peat in enabling food safety and security, and the environmental impact of extraction. It is important to note that as horticultural peat extraction accounts for only 0.05% of global peatland use, and restoration efforts often add value to otherwise degraded peat ecosystems, the environmental impact is small.

Nevertheless, to ensure a sustainable and prosperous mushroom industry, the development of alternative casings is an industry priority.

One such group that has taken on this challenge is the European consortium BIOSCHAMP, a collaboration of six countries to research, mix and test new circular raw materials and biostimulants that can improve sustainability, while ensuring the safety and effectiveness of mushroom growing.

The consortium aims to create novel casing soils using new materials with key qualities that include appropriate gas exchange, mycelium protection, excellent water holding capacity, nutrient holding capacity and are free from pests and pathogens. It also needs have suitable physical properties, including a structure that supports and protects the expanding mycelia without being a barrier to growth.

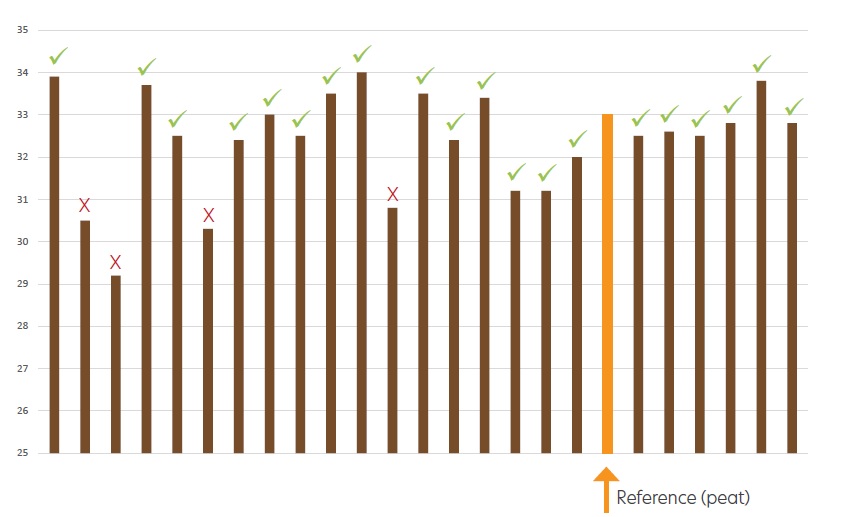

“We (Kekkilä-BVB) joined as a project partner two years ago with a goal to create a more sustainable casing soil, reducing the sector’s dependency on peat,” Folkert said. While the research is still at the trial stage, preliminary results are promising. In Figure 1 materials are not identified, but those marked with ‘✓’ provided results statistically similar to the reference peat.

Figure 1. Yields obtained using alternative casing materials (kg/m2), X denotes materials where yield was reduced; most materials tested were not statistically significantly different to peat, marked with a ✓.

“By 2024 we will be able to discuss the alternatives in more detail, but in the meantime, I feel very optimistic that a solution is not far away,” Folkert said.

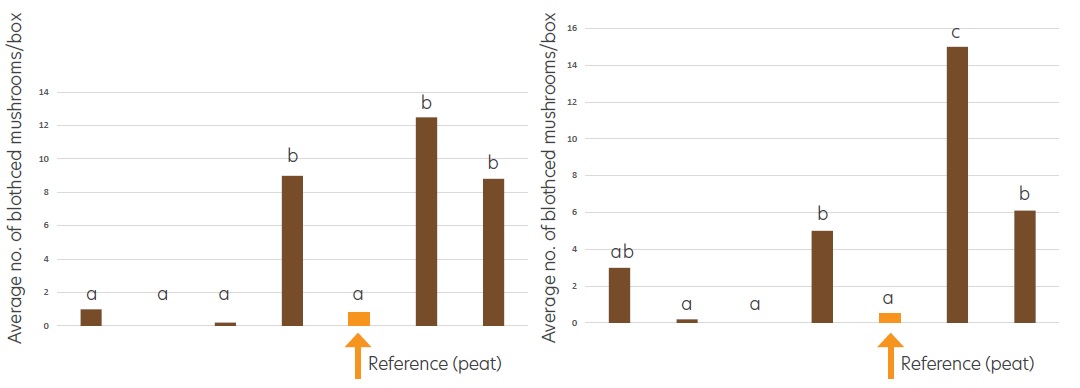

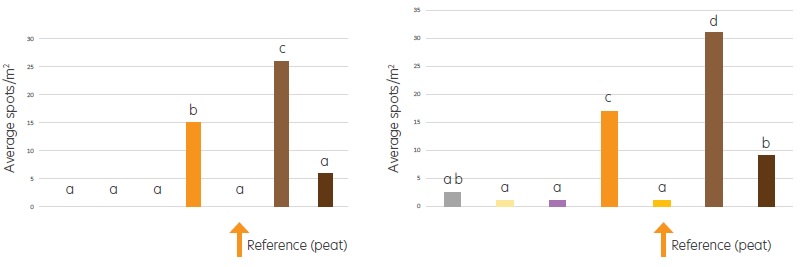

The materials were also assessed for their effects on disease, specifically number of mushrooms with bacterial blotch and occurrence of visible Trichoderma. Several materials performed as well as peat on both counts (Figures 2 and 3). Combining these results with yield data reveals several materials worth taking to the next stage of testing.

Figure 2. Bacterial blotch measured in average number of blotched mushrooms/box. Materials marked with ‘a’ are not significantly different to peat.

Figure 3. Green mould measured in average spots/m2. Materials marked with ‘a’ are promising.

What’s happening in the meantime?

While researchers toil away finding a fit for purpose peat replacement, peat will continue to be the major constituent of mushroom casing. Kekkilä-BVB are committed to the best possible practice (following Responsible Peat Production guidelines) in the sourcing, extracting, and rehabilitation of peat landscapes. which are extremely high in Sweden and Finland, where most of the peat is sourced.

Understanding Microenvironments to choose the right alternative casings

Is blending peat with something else the answer? Probably not, says Dr Ralph Noble, who has been researching the microbiology of mushroom cultivation for over 40 years. Dr Noble has turned his attention to how understanding the microenvironment of casing can help us achieve net-zero, peat-free mushroom farming. Dr Noble’s presentation focused on the properties of casing and factors that impact yield, quality, and disease.

Some background

Researchers have been searching for alternatives to peat for many years.

Dried milled peat was used in Australia up until the early 1990s, when wet dug peat became more readily available. Although the wet dug peat is bulkier and heavier, its superior water holding capacity meant it quickly became the preferred material. This is because it retains the porous structure of the Sphagnum moss from which it was formed.

Other countries are already trying to reduce use of peat, either due to cost or from necessity. For example, France and Spain commonly mix clay from local soils with peat, while China still uses milled peat, sometimes combined with rice husks and river mud.

However, it is hard to beat peat. South Africa has minimal sources of peat locally, and those it does have are protected from extraction. During the

years of apartheid, sanctions made it impossible to purchase peat externally. Local research developed and commercialised a product based on sugar cane bagasse. While this was widely used, the end of restrictions has seen farms return to the best possible casing material –wet dug moss peat.

Many options have been investigated, each with their own pros and cons, as illustrated in the table below this article (Figure 4.)

What has the science said?

If science is the process of asking nature a question, then data is her answer

Luckily for the mushroom industry, Dr Noble has been asking the right questions and has collated some useful data to answer the original question: What works and why.

When considering yield alone, peat mixed with up to 25% other materials often looks promising. Unfortunately, yield often declines as the non-peat portion increases past this level.

Some of Dr Noble’s data is shown in Figure 5. In these trials, only recycled rockwool and bark plus green waste compost could be added to peat as 25% of the total volume without negatively affecting yield.

“I don’t think the answer is in blending peat with other materials,” commented Dr Noble. “A full replacement for peat is a better option than simply trying to reduce it as a component of the mix.”

When examining potentially useful materials, it is important to consider not just water holding capacity (WHC) when saturated (e.g. after heavy watering), but also how the materials hold on to this water to slow down losses caused by evaporation and drainage.

Wet dug peat is an ideal casing because it has a high water holding capacity when saturated, and holds on to this water so that little drains out. This leaves a good supply of water for mushroom mycelium between waterings. Although wood fibre holds about 80% water when saturated, most of this is released when only a small suction is applied. On a mushroom bed, the water in wood fibre readily evaporates and drains out, leaving less for the mycelium to extract.

Conversely, green waste compost holds only 60-70% water when saturated meaning that it has to be watered frequently with smaller quantities. However, it holds on to this water better than wood fibre does when a suction is applied. The material dries out more slowly on a mushroom bed leaving a supply for the mushroom mycelium to extract.

The capacity of materials to hold water is mostly influenced by pore size, and the ability to hold water at different suctions by having a range of different pore sizes within the material or blend of materials.

Sphagnum moss, preserved as wet dug peat, has an ideal natural range in pore sizes. Avoiding excess mechanical agitation preserves this structure. However, other materials may actually benefit from mechanical intervention to improve blending of materials with large and small pore sizes (e.g. bark and clay).

Other issues to consider

Mushroom cultivation is not just a matter of producing high yields, other cropping factors must also be considered:

Material stuck to mushrooms (left), leggy mushrooms (right)

- Some materials are sticky and will cling to the mushrooms

- Some casings produce leggy mushrooms

- Over pinning can be a problem – high yield but small mushrooms

- Case run can be slower with alternative casings, increasing the time taken to grow a crop

- Irrigation practices are likely to need to change

Overpinning (left), slow case run (right)

- Risk from Trichoderma (green mould) is increased when peat is blended with other materials.

Green mould (Trichoderma harzianum) on 25% bark casing

- Some organic alternatives can also increase the risks from sciarid flies

- Conversely, bacterial blotch is reduced in some peat-based blends

Dr Noble is optimistic. Despite a few challenges, we are not too far off a peat-free future, and he wagers that by 2030 Australia will be producing high yields of quality mushrooms without peat casing.

We look forward to following the results of his work as it becomes clearer what those alternative casings might look like.

| Material | Advantages | Disadvantages |

|---|---|---|

Wet dug peat |

Free of pests and diseases Low pH and nutrient content Excellent water holding capacity Appropriate pore size, allowing air to reach mycelia Low bulk density Structurally stable and supportive |

Not sustainable due to slow regrowth of peatland (<1mm/year) Long travel distances = high freight costs Biosecurity restrictions lead to import delays Hard to re-wet if it dries out |

Coir |

Renewable and readily sourced within the region Good structure and stability Good water holding capacity Appropriate pore size Easy to re-wet after drying Low bulk density |

Must be leached to reduce salt content, requiring large volumes of water Risk of contamination (pests, diseases and chemicals) Imported, increasing freight costs Competition from other users affects price and availability |

Spent mushroom compost |

Available on farm; solves disposal problem so cost-positive Good water holding capacity Appropriate pore size Good structure and stability |

High salt content – must be leached before use, requiring large volumes of water Must be heat treated to eliminate pests and diseases |

Recycled casing |

Available on farm; solves disposal problem, cost-positive! Reduces issues with salt content in spent mushroom compost Can be added up to 1/3 without affecting yield |

Equipment needed to remove casing from spent compost Must be heat treated to eliminate pests and diseases Does not eliminate peat from growing system |

Composted wood fibre |

Renewable and locally sourced High porosity Water taken up but easily lost through evaporation and drainage Low bulk density Structurally stable |

May increase requirement for added nutrients Can become compressed Likely to require leaching or steam treatment before use Susceptible to green mould |

Green waste compost |

Readily locally available Inexpensive Moderate water holding capacity and retention Appropriate pore size May suppress some pathogens |

Variable characteristics, depending on substrates used and composting process High nutrient content (K and P) Potential for high salt content Risk of contaminants (pesticides, microbes and physical) Must be blended with other materials Relatively high bulk density |

Composted bark chips |

Readily locally available Inexpensive Large pore size |

Low water holding capacity May require leaching before use Risk of contaminants, especially if not composted correctly May contain organic compounds that inhibit growth |

Rockwool |

Pest and disease free Inert and structurally stable Free of nutrients Good water holding capacity Appropriate pore size and range Low bulk density |

Expensive – energy intensive production process plus high freight costs Low buffering capacity Can be hard to re-wet |

Used rockwool |

Readily locally available Potentially inexpensive Neutral pH and low in nutrients |

Requires processing and granulation before use Limited availability |

Vermiculite |

Pest and disease free Inert and structurally stable Free of nutrients Large pore size Extremely low bulk density |

Expensive – energy intensive production process plus high freight costs Relatively low water holding capacity |

Paper and cardboard waste |

Readily locally available Inexpensive High water holding capacity |

High bulk density Source of contaminants Can encourage mould growth |

Clays and other by-products from mining |

Materials may be readily available (some areas) Potentially inexpensive Potential yield improvement (coal tailings) Moderate water holding capacity Generally inert with stable structure Low risk of pests and disease Positive trial data exists |

High bulk density May dirty mushrooms Can adversely affect casing conductivity |

Original article by Dr Jenny Ekman and Paulette Baumgartl, published by MushroomLink (Australia) in their magazine January 2023.

Grow22 – Join us to make a difference

Kekkilä-BVB launches a virtual festival to discuss and develop horticulture and gardening – Grow21 leads the green industry towards a more sustainable future

Helsinki, Finland, 8 February, 2021 – Kekkilä-BVB, the European leader in horticulture, launches a virtual event for the extended community of horticulture, gardening and landscaping professionals to gain inspiration, learn about new trends, share experiences and drive the industry towards a more sustainable future.

”Due to Covid-19, many horticulture and gardening industry events have been cancelled or postponed. With this virtual event, taking place on 9–11 February 2021, we aim to bring light and inspiration to our current reality.”, says Juha Mäkinen, CEO of Kekkilä-BVB.

As well as a world-class line-up of inspirational keynote speakers, the event will host panel discussions, interviews, Q&A sessions and local webinars.

Day 1 will focus on securing green areas and biodiversity in urban areas. On day 2, the key focus will be on trends and the changes in consumer behaviour in the post-pandemic world. Day 3 provides us with answers on how Covid-19 is changing our industry and what the future of sustainable growing will look like.

The line-up of 35 inspirational speakers includes:

Laura Gatti, 9th of February 2021

A world-famous agronomist and landscape consultant/designer, and recognized as one of the 50 most influential green leaders in the world. She will provide us with an inspirational speech about the present and future of our green cities.

Anne Lise Kjaer, 10th of February 2021

A leading global futurist and visionary thinker, and the CEO of trend management & ideas consultancy Kjaer Global, whose visionary keynote will cover the key topics shaping tomorrow’s people and our quest for a better world.

Jussi Hiltunen, 11th of February 2021

A partner at McKinsey Helsinki, a leading global management consultant firm, will share his views on the future of the horticulture industry.

To find the registration and the full agenda, visit www.kekkila-bvb.com/growfestival

More information:

Nina Kinnunen, Director Sustainability, Brand & Communications, nina.kinnunen@kekkila-bvb.com, +358 40 7775333

Anna-Marja Vainio, Senior Manager, Communications, anna-marja.vainio@kekkila-bvb.com, +358 50 5531913

Grow21 Speakers

“Sharing knowledge put’s the customer in the driving seat”

Garden Center

As a leading supplier of potting soil to garden centers, food retailers, and DIY chain stores Kekkilä-BVB knows how the buyer’s journey has changed over the past years. Today, the demand for innovative Private Labels beside branded products is high and brings both manufacturers and retailers to a new level of co-creation.

Buyer´s journey is all about building partnerships

For Kekkilä-BVB Retail, who offers private label products as an extension line to the branded products, insight into buyers’ journey is all about sharing knowledge and building partnerships with customers. The history of Kekkilä-BVB lies in professional horticulture and goes back some one hundred years. Today it is one of the largest global players and Retail benefits from this professional horticultural experience.

Sharing knowledge

Talking to Rein Donselaar, Sales Manager Kekkilä-BVB, customer relationships are all about sharing knowledge. Kekkilä-BVB has an extensive network of internal and external data insights about products, trends and segmentation providing customers with in-depth market knowledge. Rein describes it as a process where Kekkilä-BVB, together with the customer, take control over the product and design their own recipe, tailored to the needs of the consumers. To Rein, sharing knowledge is all about giving customers the control over quality and price.

– With its twelve production plants and three laboratories, Kekkilä-BVB offers customers a world of knowledge, Rein says.

Brand positioning

But, how to position private label products and branded products in a successful combination? According to Rein, choosing a private label strategy is a matter of differentiating from competitors. Garden centers, chain stores and food retailers often use a three-step price strategy; budget, private label and branded products. Nowadays even premium private labels are being introduced.

“We help customers with positioning in terms of price point, quality, brand promise, placement against their brands and sustainability etc. We produce what our customers ask us to do. Going for budget or premium private label depends on their strategy. Together we shape the right recipe tailored to the customers’ brand promise”, Rein says.

If needed, Kekkilä-BVB also helps with the design of the private label, whether it’s a new innovative look or designed according to the customers’ brand book.

Combining a digital experience with instore choices

In the future, Rein foresees a world where the retailers are the experts and guide consumers step-by-step to the garden of their dreams, in a balanced online and offline setting. For instance, digital solutions like Google Earth makes it easier to look into a garden and help design it based on consumers’ wishes. A combination of online experience with instore choices like plants, flowers, pots, garden furniture, pavement choices, etc. will be the key to success.

– The retailers are the experts and a source of knowledge about how the online and offline world interact towards consumer behavior. The more the retailer knows about his product the more he can help customers to good choices, Rein says. “That’s why we share our knowledge with our customers”.

Text: Louise Harvig Olsmar

👉 Read more! What is peat and what makes it a great constituent as growing media?

To receive the white paper, enter your contact data so that we can send you a download link. Your data is safe with us.

Request our peat package

Kekkilä-BVB and Lidl – a customer case

Lidl asked Kekkilä-BVB for a universal potting soil ‘best in class with outstanding quality whilst being very sustainable’. Competition amongst the discount stores is high and Kekkilä-BVB designed six sustainable recipes of a very high quality and made a completely new packaging design, tailored to a young and urban audience. Kekkilä-BVB even gave Lidl the ability to offer an app were consumers get potting soil advice whilst scanning a plant in a Lidl store. This premium label called Earth Senses is specifically designed for Lidl and is available in various countries.

Practical guide to ensure the flow of goods in EU

The EU Commission presented today a practical guidance to ensure the flow of goods in the EU via so called « green lanes“. These green lane rules apply to ALL freight vehicles, independant on what type of good they are transporting. According to the guidance, any border crossing should not take longer than 15 minutes including (if applicable) health screenings and checks. This is good news for our sector as well and will hopefully ease the situation at inner-EU borders.

To access the guidance document, please follow this link.

Key elements are :

- Border crossing procedures at green lane border crossings should be streamlined and limited to what is strictly necessary. Checks and screening should be carried out without drivers having to leave their vehicles, and drivers themselves should undergo only minimal checks. Drivers of freight vehicles dont need to show any particular document (apart from identification and driving license and if necessary a letter from the employer)

- No freight vehicle or driver should face discrimination, irrespective of origin and destination, the driver’s nationality or the vehicle’s country of registration

- EU Member States urge to temporarily suspend all road access restrictions currently in place in their territory, such as weekend, night and sectoral bans

- The Commission recommends that Member States take action to ensure the free movement of all workers involved in international transport. In particular, rules such as travel restrictions, and mandatory quarantine of transport workers not displaying symptoms, should be waived. For example, Member States should not require that transport workers carry a doctor’s certificate to prove their good health. To ensure the safety of transport workers, enhanced hygiene and operational measures are also needed in airports, ports, railway stations and other land transport hubs

- Annex 2 includes a full list of recommendations to protect drivers from the corona-virus

Questions, please contact GME Europe, Secretary General Cecilia Luetgebrune.