Kekkilä PrimeFLOW brings a unique air and water management solution for growers of young plants

Today at IPM Essen Kekkilä Professional introduces a new product, namely Kekkilä PrimeFLOW, a unique substrate mixture containing renewable wood fibre. Kekkilä PrimeFLOW is produced with inventive solution in Kekkilä-BVB’s factories, which ensures uniform mixing so that the wood fibre is properly fluffed. This enables easy and smooth potting without oversized lumps of fibre or impurities. Kekkilä PrimeFLOW offers growers a product that has good air/water balance, for a competitive price compared to perlite. Kekkilä PrimeFLOW is in production and ready for orders.

Kekkilä PrimeFLOW is developed and tested to improve the growing conditions for bedding plant growers, young plant growers and tree nurseries. “We want to offer both sustainable and cost-efficient solutions for our customers. In continuous dialog with them we are constantly improving our offering for a better growing environment. Kekkilä PrimeFLOW answers some of the requirements of our customers such as products with improved drainage in finer fractions without perlite. With this new product we can bring solutions for tray mixes at a lower price and high-quality material for robotic transplanters.” says Guido Linders, Director, BU Professional growing.

Kekkilä PrimeFLOW solves several issues in small pot production

Nedeljko Basic, the product manager for Kekkilä PrimeFLOW highlights the unique benefits for the growers: “The clear benefits for the small pot grower are tangible. The wood fibre in the mixture ensures reduced shrinkage and increases solids in the mix, improving physical properties. The best usage of fertilizers and water thanks to Higher EAW (Easily available water) is one of the key features of Kekkilä PrimeFLOW. It brings along specific pore size distribution which is the most important factor for the plant’s growth. Furthermore, the optimum level of capillarity forces for all types of irrigation systems makes this product available for all small pot growers.”

Kekkilä PrimeFLOW is completing the Kekkilä FLOW family, which already includes three sustainable products that improve water management: Kekkilä SafeFLOW, Kekkilä EasyFLOW and Kekkilä SteadyFLOW.

Read more: https://www.kekkilaprofessional.com/products/ornamental-and-pot-plants/flow/

Read more about Kekkilä-BVB´s concrete sustainability cases here: kekkila-bvb.com/sustainability

Contact:

Guido Linders, Director BU Professional growing: guido.linders@kekkila-bvb.com tel. +31 (0)653273109

Nedeljko Basic, Product Manager: nedeljko.basic@kekkila-bvb.com, tel. +358 (0)406324837

Kekkilä Professional is a premier brand of high-quality growing solutions for global modern horticulture. Kekkilä Professional is a brand of Kekkilä-BVB, the European leader in horticulture. We provide products and services for professional greenhouse growers, consumers and landscapers to over 100 countries worldwide. We have strong product brands within the professional and consumer growing markets, trading under the names of BVB Substrates, Kekkilä Professional, Kekkilä Garden, Hasselfors Garden, Jardino and Florentus. Together with our customers we grow for a better future. Kekkilä-BVB is a part of Vapo Group.

www.kekkila-bvb.com

BVB Substrates introduces sustainable new innovation for acid loving crops

The new product in BVB Substrates’ portfolio, BVB Quick Rooting Acid Loving Substrate, is a mixture suitable for the cultivation of acid-loving crops. BVB Accretio is used as one of the raw materials. Its unique physical and chemical properties help crops to develop strong root systems more quickly. BVB Accretio is a new raw material made of sphagnum moss. It offers many advantages for growing acid-loving crops, such as quick rooting, which is important for enclosing the roots well while providing sufficient drainage.This ensures the availability of air to the rootzone.

“Recent research shows that adding BVB Accretio to substrates quickens the rooting of crops thanks to the increased porosity of the mixture. BVB Accretio ensures that the plant roots can access water evenly at any time due to the improved water holding capacity it gives the substrate.” says expert product manager Bram van Brommel.

The chemical characteristics of BVB Accretio are particularly suitable for acid-loving crops e.g. due to a low pH level. It provides a good pH-buffer which steadies the pH level throughout the growing stages, making the mixture reliable and stable.

BVB Accretio – a sustainable raw material

The origin of BVB Accretio is in Finland where there is approximately 300.000 hectares of land area suitable for the collection of this moss. Sphagnum moss is a renewable material, which means that it grows back after harvesting and is ready to be harvested again in 20-30 years. Research shows that the harvest doesn’t have a negative impact on the environment.

In addition to the fact that the extraction of the raw material has minimal impact on the ecosystem, it also has a relatively low weight. This means that the transport of BVB Accretio has a smaller environmental footprint.

“For Kekkilä-BVB, sustainability is about a change in how we as a company do business, taking into account the whole value chain. We are focusing on how we can help our customers in the most sustainable way. Using sustainable raw materials such as Accretio in our products helps our customers in their way of doing sustainable business.” says Guido Linders, Director BU professional growing.

Read more: https://www.bvb-substrates.nl/en/bvb-accretio-sustainable-raw-material-for-substrates/

Contact:

Guido Linders, Director BU Professional growing, guido.linders@kekkila-bvb.com,

tel. +31 (0)6 53 273 109

Bram van Bommel, Product Manager for Tree Nurseries, bram.van.brommel@kekkila-bvb.com,

tel. +31 (0)6 55 737 557

BVB Substrates was founded in the Netherlands over 100 years ago. High quality, tailormade growing media under the BVB substrates brand are sold directly to professional growers worldwide. BVB Substrates is a brand of Kekkilä-BVB, the European leader in horticulture. We provide products and services for professional greenhouse growers, consumers and landscapers to over 100 countries worldwide. We have strong product brands within the professional and consumer growing markets, trading under the names of BVB Substrates, Kekkilä Professional, Kekkilä Garden, Hasselfors Garden, Jardino and Florentus. Together with our customers we grow for a better future. Kekkilä-BVB is a part of Vapo Group.

www.kekkila-bvb.com

Urbanization demands sustainable innovations

Every week the current number of urban inhabitants is boosted by a further one and a half million people. This phenomenon is not only manifest in rapidly developing countries in Asia, but also in Europe. What are the implications of urbanisation for food supplies? How can we safeguard the continued liveability of these cities? Horticultural suppliers such as Priva and BVB Substrates invest in sustainable solutions.

Meiny Prins is CEO and co-owner of the technology company Priva. She has a clear vision of urbanisation and its implications for food supplies. ‘Cities will continue to sprawl and grow. The limit is not 10 million inhabitants, but continued growth up to 20 million, or even 50 million inhabitants. City inhabitants need clean air, a safe environment and healthy food. Cities today are surrounded by a green belt where food is produced. But ever more urban authorities are realising that growth cannot be facilitated simply by pushing the green belt further out into rural areas.’

Better quality of life

According to Prins, cities will discover that quality of life has a higher priority than economic growth. ‘People no longer accept that they are forced to live and work in poor conditions. Cities will become the driving force behind sustainable solutions that will help us save our planet, together with the business community and consumers. Cities can integrate their green belt into the urban area. That is a great step towards a circular economy’, says Prins.

Marck Hagen, director of innovation at Kekkilä-BVB since 1 November 2019 shares Meiny Prins’ vision. ‘Urbanisation is irreversible. That equally applies to the global population increase. Consequently, the demand for food continues to rise. It’s an inescapable fact that a majority of the world’s population will live in regions that experience a scarcity of water within a few years. This development is both a challenge and an opportunity for our sector. Sustainable innovations are essential to provide city dwellers with healthy food and a good living environment. That is why we are investing in substrates, which can provide the answer to this dilemma.’

Renewable raw materials

Hagen cites several examples of successful innovations that respond to these challenges. ‘BVB Sublime is a growth medium based on foam that BVB Substrates developed years ago for the horticultural sector. The medium is ideal for the plugs used in vertical farming systems. Vertical farming is the practice of growing crops in multi-layer systems under environment controlled conditions using limited water, a cultivation method that suits urban areas. The medium is also ideal for hydroponics, an efficient method of growing leafy crops.’

The rising demand for healthy food in densely populated cities logically means that the demand for substrates is continuing to grow worldwide. In his role as director of innovation, Marck Hagen focuses on renewable raw materials. ‘These “renewables” are vital to avoid exhausting our planet’s resources. The innovation BVB Accretio is renewable peat moss, a sustainable alternative to peat with similar properties. We are also exploring other options. A material that is a residual product for some may well be a sustainable addition to our raw material portfolio.’

To ensure long-term liveability of burgeoning cities, not only food but a green living environment is also fundamental. Roof gardens help purify the air, reduce the concentration of fine particles, reduce the heat build-up and create water buffers in the city. ‘Our Urbanroof substrates and BVB Greenroll contribute to the greening and cooling of growing cities. The new substrates we develop for consumers can also improve the quality of life in urbanised regions.’ (read case: A green oasis in Dubai)

Difficult climates

As a high-tech company, Priva is also investing in sustainable solutions. The company is a global player in hardware, software and service provision in the field of climate control, energy saving and optimal water reuse. Technology in the high-tech greenhouse and the opportunities offered by vertical farming enable efficient and sustainable food production all over the world.

‘You can grow any variety of tomato and almost any other fresh crop no matter where in the world. Pure Harvest – a company that grow tomatoes in the desert near Abu Dhabi – is exemplary of this principle. In difficult climates, you can make this a profitable enterprise. These developments are moving forward rapidly’, says Meiny Prins.

Values and SDG

Priva and Kekkilä-BVB both see a role they can play in creating these kinds of sustainable systems. Prins: ‘We help growers generate greater profitability at the end of the year while using a lower input of natural resources. We want to grow this added value. Profit is not an end in itself, but a condition for continuity. Priva is value driven instead of profit driven’, says Meiny Prins.

That philosophy is shared by Kekkilä-BVB, who strive for ‘sustainable everyday living’. The values established by the company reflect the Sustainable Development Goals (SDG) set out by the United Nations. Marck Hagen: ‘In a regime of sustainable business practice, both nature and business can flourish. We endorse and operate in line with four Sustainable Development Goals: creating good health and well-being for people, sustainable food and living environments, developing recycled material for green cities and the living environment and safeguarding and ensuring biodiversity for the future. It creates a sense of purpose and power when companies work together to pursue these goals.´

Photo of Meiny Prins: Priva BV

This article was originally published in our professional growing customers magazine Bloom in January 2020.

World Wetlands Day: An introduction to peatland

“If your feet are wet but you can’t swim, then its peatland”

For this year’s World Wetlands Day, we decided to dedicate our blog to a very particular kind of wetland, peatland. We invited the President, one of the two Vice-Presidents, and Acting Secretary General of the International Peatland Society (IPS); Marko Pomerants, Jack Rieley and Susann Warnecke respectfully, to give us an introduction to peatland.

What is the difference between wetlands and peatlands?

Peatlands are wetlands but not all wetlands are peatlands. A wetland is an ecosystem which is either permanently or temporarily flooded or full of water. This includes everything from bogs, swamps, coastal shallows and more, but there is a distinction between freshwater wetlands and saltwater wetlands.

How do you define peatland?

Peatland is a type of freshwater wetland with an accumulation of partly decomposed plant matter. Specifically, the water, acidity levels, lack of oxygen and the incomplete decomposition of organic materials leads to accumulation of organic matter over time which is later referred to as peat once it reaches an approximate 10-20cm level of thickness. It is important to note that this is a broad description as there is no fixed definition as peatlands and peat can develop in every continent in the world and from different plants in different locations. Colloquially though, you can say if your feet are wet, but you can’t swim then you’re in a peatland.

Where does peatland form?

In short, on every continent, 50% of wetlands are peatlands. 12% of global peatlands are tropical peat swamp forests, commonly known as rainforests in the tropics. The remaining 88% of peatlands are non-tropical with the majority situated in the Northern hemisphere as we do not have as much land mass in the Southern hemisphere. Where they form, even regionally, can vary. In Scotland you have blanket bogs which are formed way up on mountain ridges, whereas in Finland you see them forming in shallow areas, in former lakes as well as land that is still being lifted after the last ice age, while in Siberia they are often affected by permafrost. Due to the wide range of causes, the ages of peatlands throughout the world can vary from a few hundred to tens of thousands of years.

What are the variations of peatlands and what does this mean for the peat?

In Northern Europe, the bog moss Sphagnum is the main peat forming plant, but depending where you are on earth peat can be formed by completely different plants, for example in the tropics in Southeast Asia the main peat formers are rainforest trees that can be more than 30 meters tall. All over the world, peatlands are natural ecosystems populated by a myriad of different plants ranging from primitive low-growing mosses to massive trees. This leads to peat with varying biological, chemical and physical characteristics of incredible complexity. In the tropics peat has a very high wood content, including branches and trunks making its qualities different from Sphagnum peat and difficult to extract to use for energy or growing media.

Talking of growing media, which peat has the best characteristics for growing?

When it comes to growing media used by gardeners or commercial growers of food and ornamental plants there is a difference between fen peat which comes from lowland peatland, that received nutrient-rich ground water in addition to rain, and raised bog peat, which forms in waterlogged, acidic, nutrient-poor conditions at the end of mire succession from open water wetland when the area is fed only by rainwater. Only special mire plants can survive in acid peat bogs. Fen peats contain an abundance of sedges, grasses, and other emergent plants such as bulrushes collectively referred to as reeds together with a large variety of other flowering plants. Fen peat can provide a nutrient-rich ingredient that can be used for some types of growing media. Most of the peat used in horticulture growing media is harvested in the northern hemisphere (especially Europe and North America) from raised bogs, they are fed by rainwater only and that have an abundance of Sphagnum mosses. Peat is an important ingredient for growing media on account of its availability, quality, reliability, and lack of disease or pest vectors that provides a more neutral or “clean” substrate which is high in demand as it can be used to support the growth of almost all plants.

Why are peatlands important?

The importance of peatland can be divided into three sections: Environmental, social, and economical.

Environmentally, peatland is obviously the home to a large variety of flora and fauna throughout the world. Peatlands although they cover only 3% of the global land surface are one of the largest stores of carbon extracted as carbon dioxide from the atmosphere by the peat-forming plants. It is said that peatlands store more carbon in their peat than all the world forest above ground biomass. However, because peat is around 90 per cent water peatland plays a key role in the water cycle by detaining, storing, and releasing rainwater it makes it also important for human communities.

Socially, peatlands have a long history with humans. There are folktales that they are home to fairies and trolls, they are sites for artefacts as people hid their possessions, and they were used as shelter during difficult times such as war and famine. They were sources of food and material for shelter. These days they offer people a place to walk, to be outside, to collect berries and mushrooms, and enjoy the fresh air.

Economically speaking, peat has been harvested for not just hundreds but thousands of years. The peat was used for insulation of houses, until recently it was burnt for heating, and of course animal bedding. The peak of harvesting came in the late 18th and early 19th century due to the reliance on animals and the need for bedding. During the World War I, there were so many horses they had to dig peat bogs almost out of existence, for instance in the Netherlands. In the modern-day world very little is extracted. There are 4 million km2 of peatlands in the world and we harvest just 4000km2, of which only half of that is used for horticultural purposes. Burning peat for energy has almost completely ceased due to high emission right costs.

Today the activity happening to peatlands is restoration and rewetting. This is happening across the globe on near pristine as well as former industrial sites, afforested sites, in tropical peat swamps and even urban areas.

What are the biggest challenge peatlands face today?

In developed countries peatland drainage and degradation has taken place over centuries mainly for agriculture – arable crops and livestock bedding and grazing, but also for domestic purposes, burning and water supply. The priority is to rehabilitate degraded peatlands back to their original peat forming, carbon storing condition. This is a major challenge that has already started in many countries, but it involves dam construction, rewetting, re-vegetating (with Sphagnum) and is costly.

In undeveloped and developing countries where the importance of peatlands as carbon stores is just being realised and, hitherto, unknown peatlands are being discovered the challenge is to persuade governments not to embark on wholesale development for agriculture or plantations of traded commodity. This will only create similar problems found in the developed world of peat oxidation (decomposition), subsidence, flooding and eventual loss of economy and livelihoods.

If peatlands and peat must be used this must be done in a responsible manner with after use plans in place and parallel restoration of previously degraded peatland as offset.

Endnote

There is an odd myth that extraction of peat is the biggest threat to peatlands but that isn’t true. It is mainly agriculture, forestry and climate change which are destroying the ecosystems of many peatlands. Globally, greenhouse gas emissions from drained peatlands accounts for around 5% of global emissions. Statements usually say this comes from agriculture, forestry and peat extraction, implying that these contribute equally. In fact, agriculture on peatland soils contributes 75% (of the 5%), Forestry about 25% (of the 5%) while peat extraction contributes less than 0.1% (of the 5%). This puts the matter in perspective.

About IPS

The International Peatland Society is the only international organisation that is dedicated to every aspect of peatlands, including peat industry. Its more than 1600 members are mostly scientists and other experts, but it also has around 300 corporate company members. IPS aims to be the leading international organisation promoting the responsible management and wise use of peatlands and peat with the mission to serve all those involved in peatlands and peat through the promotion, gathering, exchange and communication of knowledge and experience, by means of events and projects which address key issues, including climate change, biodiversity, the need for responsible use and restoration. Learn more here.

About Marko Pomerants

Marko Pomerants is a qualified Geological Engineer who has worked in multiple positions within the Estonian government including Minister for Environment a role in which he signed the Paris climate agreement on behalf of Estonia. He is the President of IPS.

About Jack Rieley

Professor Jack Rieley is a semi-retired academic who specialises in botany, peatland ecology and nature management. He has been a member of IPS since early in its formation and is one of two Vice-Presidents of the organisation.

About Susann Warnecke

With a background in Business Administration Susann Warnecke has been with IPS for over two decades and is currently their Acting General Secretary.

Greener urban environment through circular economy

Meadows and nutrient recycling increase the diversity of the built environment above and below ground

The debate around nutrient recycling in Finland often focuses heavily on the countryside and agricultural recycled fertilizers. However, the nutrients recycled in the growing media also end up back in the built environment. As more and more natural meadows or green roofs are added to cities, biodiversity will also increase.

Helsinki sees many opportunities for meadows

All traditional biotopes have been assessed as endangered according to the Finnish Environment Institute’s endangered habitat assessment in 2018. Areas, fresh meadows, lake and riverside meadows, among others, were assessed as extremely endangered. The urban meadow area provides important ecosystem services, and plays an important role, not only as a habitat for endangered plants but also as a habitat for pollinators, other insects, birds and mammals. In addition, the meadow is used for recreational use, as part of stormwater management and creates landscape aesthetics. In many places, meadows are also part of an important cultural landscape.

In Finland, many cities have included urban greening and especially meadows in the park areas as part of their goals. In Helsinki, for example, projects have been implemented to establish urban meadows. In the “OmaStadi” project, city residents can vote for development sites in the city themselves, and in 2019-2020, residents wanted to allocate city funds to turn park lawns into meadows with the goal of increasing biodiversity and carbon sinks in the city. Ten different park sites were selected for the project, where new meadow areas were established from different starting points.

The city has also begun to add and restore meadows to the landscape in other open areas, where either wilderness zones have been formed as a result of construction or old meadow areas have been buffered. The aim is to take the meadows into account already at the construction planning stage. The city’s meadows have been surveyed and the care work is guided by the city’s Detailed Nature Management work instructions “Meadows and landscape fields”. In addition to increasing carbon sinks and preserving natural values, the benefits of meadow projects also include the cost savings created by meadows that require lighter maintenance. In the coastal areas, meadows may in the future be able to limit the increase in the goose population, which has caused problems in the city.

In Helsinki, meadows are also being designed and built more actively in the private sector than before, and designers can see opportunities for meadow sites in their work, even where previously the only alternative was traditional roofing, stone or asphalt. Today, you can see thriving meadows on the roofs of buildings in different parts of Helsinki. The design already considers the usability of meadows from very small sites to large entities.

The importance of meadows in urban greenery has also been recognized in Kekkilä-BVB’s operations, and different types of meadows already have their own growing media to meet the growing media environment requirements of the biodiversity site.

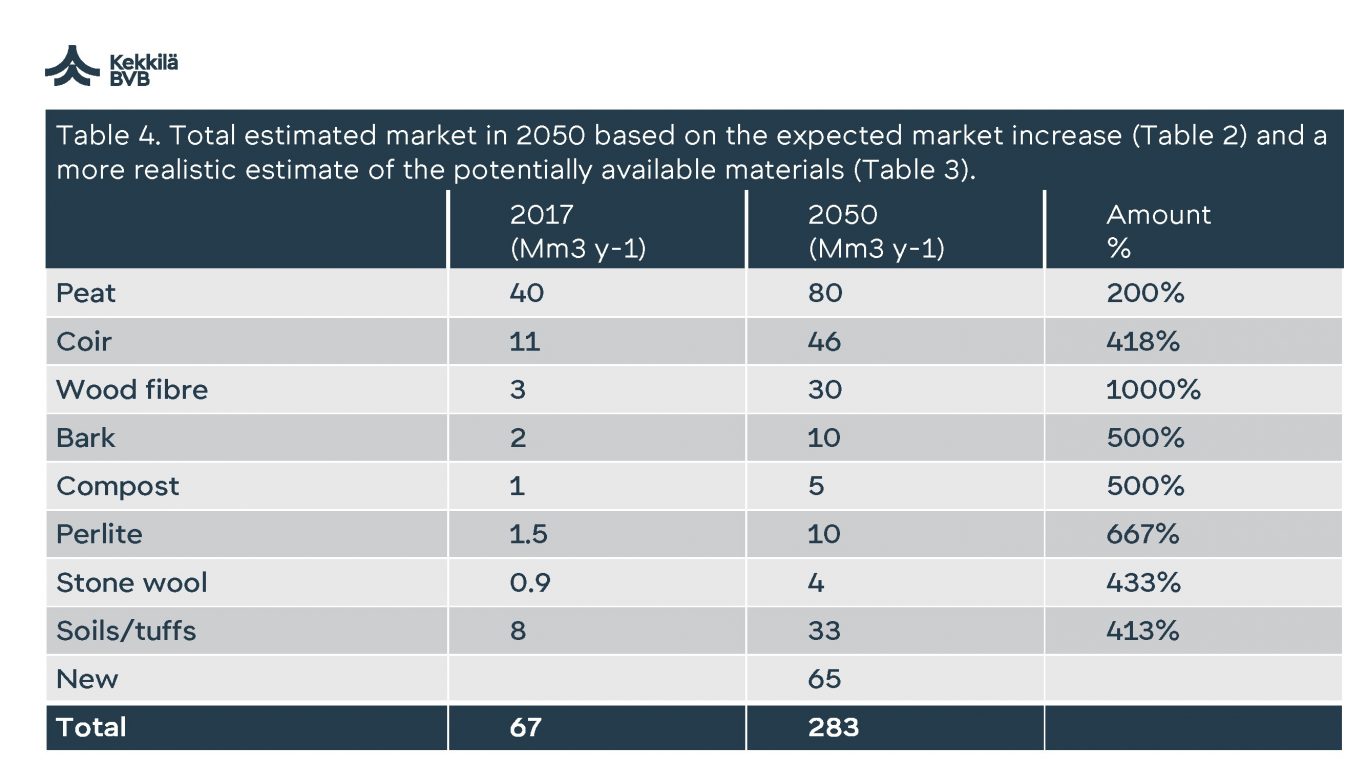

Increasing diversity and circular economy solutions are at the heart of landscaping growth media

Utilization of recycled raw materials plays a key role in Kekkilä’s growing media production and in Finland Kekkilä-BVB is a strong player in the circular economy. In a changing world, large megatrends are also driving growing media production. Among other things, climate change, digitalisation, the requirement for a sustainable product life cycle and urbanization will dramatically increase the cultivation in growing media over the next 30 years, which will significantly increase the need for growing media production. Traditional growing media materials will retain their position, but the use of renewable raw materials such as compost, for example, is expected to increase fivefold. In addition to existing materials, new raw materials will still be needed, which BU Landscaping & Recycling is actively exploring.

The changes in Kekkilä-BVB’s operations are already visible, for example, in an effort to further increase the use of recycled materials and nutrients. Compost will continue to play a significant role, but there is also a desire to increase the share of industrial by-products. The goal is to increase the share of recycled materials from the current thirty percent to forty percent in landscaping growing media production by the end of 2022. Ninety percent of the nutrients used are already recycled.

Compost not only fertilizes the growing medium, but also adds organic matter important to microorganisms, plants and fungi to the growing medium. Organic matter improves water retention and flow, acts as a nutrient store and reduces nutrient leaching, as well as improves soil structure.

From a nutrient recycling perspective, whether it was the construction of new meadows, or more traditional park construction and grasslands, landscaping is a route for recycled nutrients back to urban environments.

CASE HELSINKI: Plant roofs on Capella Park Park

CASE HELSINKI: Plant roofs on Capella Park Park

VRJ Länsi-Suomi Oy has implemented a diverse plant roof for an apartment building company in Helsinki. The site consists of two residential buildings, the roofs of which were supplied with Kekkilä’s compost-fertilized roof garden soil. The project was designed by the landscape architectural firm LOCI.

“Until a couple of years ago, this was an exceptional destination,” Henrik Bos from VRJ says. He is very pleased with the target and calls for an open-minded attitude towards the implementation of green roofs. “The destination is a bold direction to increase the diversity of urban green. Meadow-like vegetation also attracts pollinators”.

This article by Petra Salonen and Hanna Rummukainen was originally published in Grow Magazine.

Kekkilä-BVB offers landscaping services in Finland, Sweden and Benelux:

Kekkilä’s recycling services (FI) Kekkilä Landscaping (FI) Hasselfors garden Landscaping (SE) BVB Landscaping (NL)

Peat and after-life concept

Sustainable peat harvesting and after-life

Together with stakeholders, Kekkilä-BVB will develop the sustainable harvesting and after life concept for peat bogs. We own peat bogs in Finland, Sweden and Estonia. To ensure sustainable harvesting and after life processes, we will combine current best practices with a future look. A part of this is RPP certification.

1 Select peat area

Kekkilä-BVB peat is harvested only from carefully selected sites where specific extraction permits have been obtained from the local government. These areas are selected, in part, because they have no conservation value. We are not harvesting peat from protected areas. In European Union, peat extracted for fuel or horticulture is harvested from only 0.4 % of all peatlands.

The most regulated companies are those that have an impact on peatlands. From the initiative, it takes several years until all permissions are granted and extraction of peat can start. This includes assessing the site for its conservation values as well as making specific plans to ensure that the bog can be regenerated, when the peat extraction is finished.

2 Preparing for harvesting

After obtaining the necessary permits a series of ditches is dug across the peatland to drain water from the bog. This allows the surface the bog to dry out in order to enable peat extraction. In its natural state the peatland has an extremely soft surface which prevents machines to operate on the bog. It can take up to three years until extraction can start after the first ditches have been excavated.

Responsible Produced Peat (RPP)

By 2024, Kekkilä-BVB will have 80% of used peat RPP certified. Responsibly Produced Peat certification ensures that peatland will be used, managed and restored in a responsible way. The RPP certification system does not allow peat extraction from high conservation value areas.

It stimulates peat extraction from highly degraded areas followed up by appropriate after-use measures. It also implies leaving all ecological valuable areas, with or without a nature conservation status, undisturbed. Responsibly Produced Peat certification secures the best possible development after completion of peat production, with preference for restoration.

3 Harvesting

In Kekkilä-BVB the best available technology (BAT) is used for the water protection in the preparation and production of peat in order to protect the environment and to ensure sustainable production. Peat producers are under very strict regulations. However, we are not sustainable just because the law says so. It is our values and most importantly our customers, which oblige us. We are setting the industry standards as member of Growing Media Europe (GME). We follow EPAGMA’s strict Code of Practice for Responsible Peat Management and are working actively to establish the environmental certification called Responsibly Produced Peat.

When peatlands are drained and degraded, they emit CO2 (carbon dioxide). These degraded peatlands can be perfectly used for peat production. Their rehabilitation afterwards will reduce the emission of CO2 significantly. About 58 % of the peatlands in the EU are degraded.

Different types of sphagnum peat for growing media

The colour of sphagnum peat – white, brown or black peat – reflects its degree of decomposition. The level of decomposition is expressed in the von Post scale and divided into ten classes from very slightly decomposed (H1-H2) to completely decomposed peat (H9-H10). The best peat for substrates is from H1 to H6 in the von Post scale.

Different types of peat are physically and chemically different. For example, dark or “black” highly decomposed sphagnum peat has the highest water holding capacity, whereas the white sphagnum peat has the highest air capacity. Calcium and magnesium concentrations as well as pH-values also vary between the different peat types.

Peat from different sources varies also biologically and in microbial composition. Generally, blond or light-colored peat (H1-H2 in the von Post scale) are known to be very disease suppressive. This is because they can harbor high populations of ‘friendly’ microbes such as Trichoderma and Streptomyces species, which have shown to reduce the levels of pathogenic microbes in soil.

Looking for peat we go to drained bogs with extraction permits, if the bog is untouched or protected, we do not go there. The peat can be harvested roughly from May to September, when the weather is warm, and the surface of the bog dry enough. Horticultural peat is extracted using two different methods to produce two types of peat – milled peat and block peat.

Milled peat

To produce milled peat, 1–3 cm thin layers of peat are milled or harrowed loose from the surface of the drained peat bog. After several days of drying under the sun the peat is sufficiently dry (approximately 40–45% moisture content) to be harvested. It is collected from the surface of the peat bog by vacuum harvesters or collected from previously built ridges. Stockpiles of peat are formed at the edge of the bog and covered. Finally, when required at the factory, the peat is transported for further processing.

Block peat

In order to produce block peat, big blocks of peat are dug out up to a depth of approximately one metre. These blocks are left on the surface of the bog to drain excess water. As the blocks dry they are turned and finally piled manually in small piles to dry until they are dry enough to be processed in the substrate producing unit.

4 After-use for regenerating the bog ecosystem

Once peat extraction is finished the land is still valuable. We make sure life continues in the bogs long after we leave them. Nature is often richer then before we came. The land can be used for other purposes which have been pre-determined. The after-life of a peat bog is often determined by 2 factors. First, we harvest from owned and rented peat bogs. Whereas with the owned peat bogs we retain control during the after-life stage, with a rented bog the owner makes the final decision. However, in both cases, after life is determined in the harvesting permit. The second factor is the natural state of the peat bog. Due to natural factors, some bogs are more wet than others making them more suitable for re-wetting. Others naturally stay dry making them more suitable for forestry and agriculture.

The most common types of after-use are forestry, agriculture and re-wetting. During the process of re-wetting, ditches are blocked in order to re-wet the area and native plants are planted to encourage the regeneration of a natural bog ecosystem. In many cases, the restored areas have even higher biodiversity than before peat production.

During the re-wetting, the emission of CO2 is significantly reduced, and the bog will again start absorbing CO2.

We at Kekkilä-BVB are constantly studying and testing alternative materials. All materials have their pros and cons and none of them is perfect. However, peat performs best in overall comparison combining both quality and environmental criteria.

Small carbon foot print for transport

Peat has a low bulk density and is easy compressible. This makes it very fuel efficient for transporting over long distances. This helps to keep transportation costs low and to reduce impact on climate change.

A comparison – this is how much peat we use at Kekkilä-BVB

Let´s imagine that all EU peatland was found in Finland. That’s 282 000 km2 which is 92 % of Finland’s area. Peat producers use 0.4 % of the total 282 000 km2. That’s about 1 100km2. And only half of that is used by companies like Kekkilä to grow something. That’s about 500 km2 and that is smaller than the area of Helsinki. In the whole of EU!

Will there be fit for purpose substrates also in the future?

Arjan Zwinkels

The world is facing a great demand for substrates in the future. According to Arjan Zwinkels, Product Development Manager at Kekkilä-BVB, a significant part of the demand will still be peat.

- Peat will still be important in the future, partly for its safe and buffering features, partly because of the great amount of substrate needed in the future, Arjan says.

According to Arjan, it is estimated that the world will use twice as much peat in the future as is used today. Peat is safe, it buffers water and it is free from pesticides and bad fungi. It is also very safe for the grower; it holds the right amount of water.

- Peat is free from nutrients and can easily be mixed with other sustainable raw materials or organic fertilizers, Arjan says.

Peat as a base in mixtures is the future

Due to the great amount of substrate required in the future, the need for new raw materials will also increase. The use of wood fiber, bark, coir, compost, perlite and sphagnum moss will also rise. The growing media constitute today at Kekkilä-BVB is peat complemented with perlite, coir and wood fiber. In the future it will be 40%-50% peat mixed with different kinds of existing or new materials.

– Peat as a base in mixtures will remain due to it´s capacity of being safe and have the capability to buffer water, nutrients and pH, Arjan says.

Offering new mixes of growing media raises the demand for advice on ´how to grow in new materials´.

- Growers need to know how to grow in new materials, we can support them with that knowledge, Arjan says.

Wood fiber, sphagnum moss and bark are renewable, sustainable raw materials. While peat has a higher carbon footprint, coir has a higher water footprint due to the washing process.

- You also have to buffer coir with calcium and then you have to transport it, nor does coir buffer as much water as peat either, Arjan says.

Responsible Produced Peat – RPP certification

Swedish, Finnish and Estonian country specific legislations regarding peat harvesting are very strict and harvesting is done in accordance with local regulations. On top of these legislations we proceed with RPP certification. When harvesting, peat is harvested from degraded areas, areas that have been drained by earlier generations. Harvesting is nowadays never done in untouched peat bogs. RPP certification ensures that peatland will be used and managed during and after harvesting in a responsible way.

The RPP certification system does not allow peat extraction from high conservation value areas.

The system stimulates peat extraction from highly degraded areas followed up by appropriate after-use measures. It also implies leaving all ecologically valuable areas, with or without a nature conservation status, undisturbed. Responsibly Produced Peat certification secures the best possible development after completion of peat production, the preference being restoration.

Read more about peat harvesting and afterlife concept here.

For more information please contact Arjan Zwinkels.

“We want to anticipate the demand for resilient plants”

Gipmans Planten investigates sustainable cultivation systems.

Gipmans Planten investigates sustainable cultivation systems.

Plant resistance is an important topic at Gipmans Planten. Erik Gipmans interprets sustainable cultivation as replacing crop protection products for resilient plants with the ability to ward off pathogens themselves. Substrates are important to him, because they add quality at the start of the chain. ‘The demand for sustainable substrates is currently highly relevant, so that we can position our products properly on the market’ he believes.

The name Gipmans is firmly embedded in Greenport Venlo. In a year’s time, the plant nursery will celebrate its 50th anniversary. The company enjoys an ideal location from a logistics perspective. Vegetable plants and herbs grown outdoors and under glass find their way to end customers mainly in the Netherlands, Belgium, Germany, Switzerland, Austria and Northern Italy.

Brothers Jos and Erik, and their cousin René Gipmans, form the executive board, together with financial director Li-Ang Yah. Very recently, the company increased in scale again by merging with A. Scheurs in nearby Sevenum. This nursery specialises in cultivating field-grown vegetable plants. Both companies will cooperate intensively on innovation and IT.

Long-term relationships

‘We invest in long-term relationships’, says Erik Gipmans. The company has a large number of permanent employees who have worked at Gipmans for many years, and enjoys a close, loyal relationship with its extensive base of regular suppliers and customers.

The relationship with BVB Substrates – Euroveen has a long, stable history. ‘In fact, I can’t recall a time when the potting soil wasn’t supplied by Euroveen in Grubbenvorst. That’s also really convenient in logistic terms as they are literally just around the corner, no more than ten minutes from our company.’

Gipmans gets through 60,000 m3 of potting soil annually. Between mid-December and mid-August, between 20 and 30 trailers drive back and forth daily to supply mixtures for the press pots. There is also a constant stream of organic potting soil for the 10-hectare herb nursery Especia.

Herb nursery

Cultivating herbs started as seasonal activity, a useful way of utilising the space outside the growing season for plants that needed to be grown in heated greenhouses. Now herbs are an indispensable ingredient in every modern recipe. The herb nursery has therefore evolved into an independent branch of the plant nursery.

The assortment comprises 16 different kitchen herbs, of which basil takes the largest share, followed by parsley and mint. Erik: ‘We have built up many of the skills required to grow herbs ourselves. For example, mint is not easy to grow. We are staring to master the art now.’

Growing herbs has led to intensive contact with the retail sector. Supermarkets not only place demands on food safety, but also on sustainability. This extends to both the packaging materials and the raw materials, including the potting soil. ‘Those demands are very compelling and important’, explains Erik. ‘We must be able to market products with good sustainability credentials.’

No concessions

Sustainability is a priority at Gipmans. The amount of raw materials we use every year has immense consequences on vulnerable regions’, he continues. ‘So, we have given ourselves the challenge of using potting soil in a better, more responsible way. This has also been communicated with BVB Substrates.’

In concrete terms, Gipmans is running trials with smaller press pots, which effectively reduces the volume by 15%. But it’s no easy task. Smaller pots, with hollow spaces for example, must still enable the same vigour. ‘We absolutely can’t make any concessions on the quality of our final product. In fact, a minor glitch at the start of cultivation can have a significant knock-on effect in further links of the cultivation or wider supply chain.’ This not only applies to vegetable plants, but also to the herbs which have to remain usable for a few weeks after they have been bought by consumers.

Sustainable potting soil

Another route to more sustainable use of potting soil is whether accelerating the recovery and regrowth of peat regions after the raw material has been harvested is possible. Gipmans cannot answer this question, but it clearly falls in the domain of the potting soil company.

Replacing peat with another raw material is another option. ‘We are looking for a product with the same properties as black peat. Black peat is still an indispensable ingredient, but it is the least sustainable component in potting soil mixtures’, says Erik. Gipmans and BVB Substrates have close and intensive contact in the form of trials aimed at improving the composition of blends and developing a new substrate. ‘I expect a breakthrough with a product that can successfully replace a percentage of the black peat in the short term and eventually completely replace it.’

Resistant plants

A subject that particularly concerns Erik is disease control, or plant resistance. The nursery has a special responsibility in this area, he believes. The recent pressure of viruses in vegetable crops is increasing the urgency of this subject. ‘The question is no longer whether we will see outbreaks of certain diseases, but when’, he explains.

‘We are researching integrated, vertical cultivation systems. This is teaching us that plants remain disease-free in controlled systems’, he continues. ‘So, growing using a minimum of crop protection products is already possible in principle. We also want to discover how to make young plants unattractive to pests, for example aphids. In other words, how we can boost the resistance of our plants.’

Are customers already asking for plants with higher resistance? ‘No, not yet. But we want to anticipate that demand and learn to understand the underlying system. The focus of customers is on the use of pesticides and the levels of residues left behind on products. I predict that in the future we can eliminate that discussion.’

What he does expect to intensify though, is the debate surrounding the microbiome balance. Attention for food safety scandals, where bacteria were found that cause food infections, is becoming increasingly important. ‘That means we must make every effort to safeguard food safety.´

Photos: Pieternel van

This article was originally published in our professional growing customers magazine Bloom in January 2020

“Cities will be the driving force for sustainable innovations”

Rapid urbanization, an increasing global population and the fact that 2/3 of the population within 7 years from now will be living in areas where there is a lack of water affects us all. These facts are why we are investing in finding new raw materials and products to cultivation on substrates. This is also why Marck Hagen, our Innovation Director, chose to work at Kekkilä-BVB.

-With a growing global population, we need to produce more food with high quality. Finding new sustainable raw materials in making new substrates and products for cultivation on substrates is one way to invest in the future, Marck says.

Cities will become the driving force behind sustainable solutions and innovations that will help us save our planet. As one of the largest growing media companies in Europe, Kekkilä-BVB can be a forerunner in the sector showing how plants can be grown using less resources.

-Recent research shows that adding sphagnum moss to substrates is beneficial and sustainable in more than one way, Marck says.

Facing expanding urbanization and a growing population, the need for food is increasing. To be able to grow food as close to its consumption as possible, we need to find new sustainable raw materials, products and smart services which take water usage into account.

-Sustainable innovations are essential to provide citizens with healthy food and a good living environment, Marck says

Sphagnum moss – rapid regrowth after harvesting

Sphagnum moss has been used for different purposes for centuries. Sphagnum moss grows on the top of peat bogs and has not started the process of decomposition like peat. The main reason to use sphagnum moss as a raw material for substrates is that it is a living material. As a living material it regrows back relatively quickly on the peat bog after removal.

-Research shows that Sphagnum moss has started to grow again just after a year of being collected. It grows, approximately 10 mm per year. The collecting cycle is estimated to be 20-30 years, Marck says.

During the second year after collection, cotton grasses have often taken over the sites, and while cotton grasses continue to dominate in the third year, white mosses have already covered up to 50% of the area. In different peatland areas, the order and pace of regrowth may vary greatly. The Natural Resources Institute in Finland is currently researching the regrowth of moss.

Fast rooting speed and even water distribution

Recent research shows that adding sphagnum moss to substrates is beneficial and sustainable in more than one way. Mixing sphagnum moss in substrates allows for more porosity and therefore more available water for plants. Porosity ensures better drainage and there is always enough air available for the growth of roots. This means faster rooting and a shorter growing time. The addition of sphagnum moss to a mixture ensures a quick even water and nutrient distribution. Sphagnum moss has a large water holding capacity which means that less water is required for crops that grow in mixtures with this raw material added to it, as more water is held in the substrate.

– Sphagnum moss is easily adjustable with other raw materials, Marck says.

Kekkilä-BVB R&D center in De Lier

Kekkilä-BVB has a R&D center in De Lier in the Netherlands doing analyzes of the raw material and development of new products. Quality requirements are tested both internally and externally. Our laboratory is equipped with the most modern facilities and techniques. We test our new products extensively before we introduce them onto the market. Financial aspects are also taken into consideration, both from the producer side and from the view of the customer. Pilot-testing with customers and the afterlife of the product is also important. Every product must meet high requirements.

-In this way you are assured of the best quality throughout, Marck says.

More information about sphagnum moss (as raw material named BVB Accretio).

BVB Substrates and BVB Accretio

Link to article: Sphagnum moss and it´s sustainable ecosystem.

Any questions? Please contact Marck Hagen.

Author: Louise Harvig Olsmar & Kari Silokangas

Kekkilä-BVB introduces sustainability roadmap for 2030

KEKKILÄ-BVB PRESS RELEASE 28.1.2020

Kekkilä-BVB has set demanding targets to become a net positive company by 2030, guided by our sustainability roadmap with eight concrete targets. One example of Kekkilä-BVB´s sustainability actions is to launch products containing sphagnum moss for professional growers and retail customers.

“It is quite natural for horticultural companies to talk about sustainability, since we are all contributing in making the world a greener place one way or the other. But that is not enough. It´s all about how we do it”, says Juha Mäkinen, CEO of Kekkilä-BVB.

Kekkilä-BVB became the leading horticultural company in Europe after Finnish Kekkilä and Dutch BVB Substrates joined forces.

“With big size comes also big responsibility. It is our obligation to promote biodiversity and to participate in preventing the effects of climate change. We have taken the stand to be a promoter for sustainable horticultural business and to enable our customers to meet their sustainability goals”, Mäkinen says.

Sustainability roadmap steers actions

Kekkilä-BVB´s sustainability work is guided by a sustainability roadmap. It consists of four focus areas with measurable targets. These focus areas are related to the wellbeing of people in the value chain, creating sustainable new innovations for food production and living, promoting circular economy and enhancing biodiversity.

“Concreteness is very much needed in sustainability work. This was a very clear message both from our customers and personnel when we made our sustainability roadmap. One way to add concreteness is to openly measure the negative and positive impact. This is why we are participating in Growing Media Europe´s work in calculating LCA (Life Cycle Assessment) for different growing media materials. This builds the base for the sustainability standard for the European growing media industry”, concludes Mäkinen.

From talk to action

An example of Kekkilä-BVB´s sustainability driven business approach is the launch of substrates containing sphagnum moss at the global horticultural fair, IPM Essen.

Sphagnum moss grows on top of the peat bogs and has not started to decompose like peat. As a living material it regrows relatively quick. Less water is needed for crops grown with sphagnum moss, since it has a large water holding capacity. Tests have also shown excellent growth results.

“To ensure our customers’ success and that the growth results are optimal, we have done extensive tests before launching our products with sphagnum moss. We see that as part of our responsibility.”, adds Mäkinen.

Since sphagnum moss is a novelty raw material and acts differently than peat, it is not yet RHP (quality mark for substrates) certified. Kekkilä-BVB is co-operating with RHP to have it certified according to RHP´s standards.

Read more about Kekkilä-BVB´s concrete sustainability cases here: kekkila-bvb.com/sustainability

Contact:

Juha Mäkinen, CEO, Kekkilä-BVB: juha.makinen@kekkila-bvb.com, tel. +358 40 046 4549

Nina Kinnunen, Director, Sustainability, Brand and Communications: nina.kinnunen@kekkila-bvb.com, tel. +358407775333