Growing media

A substrate, also known as growing media, are the materials in which plants are grown. Usually it is a mixture of components that provide water, air, nutrients and root support to plants.

Kekkilä-BVB is a sustainable growing media company who constantly aims to make peoples lives and their environments better. We want to be as transparent as possible about our efforts and therefore we made this page so people can learn. Not only about our substrates, but about the materials in general. Why we chose them? How we harvest them? How do we see them in the future?

Which substrate is sustainable?

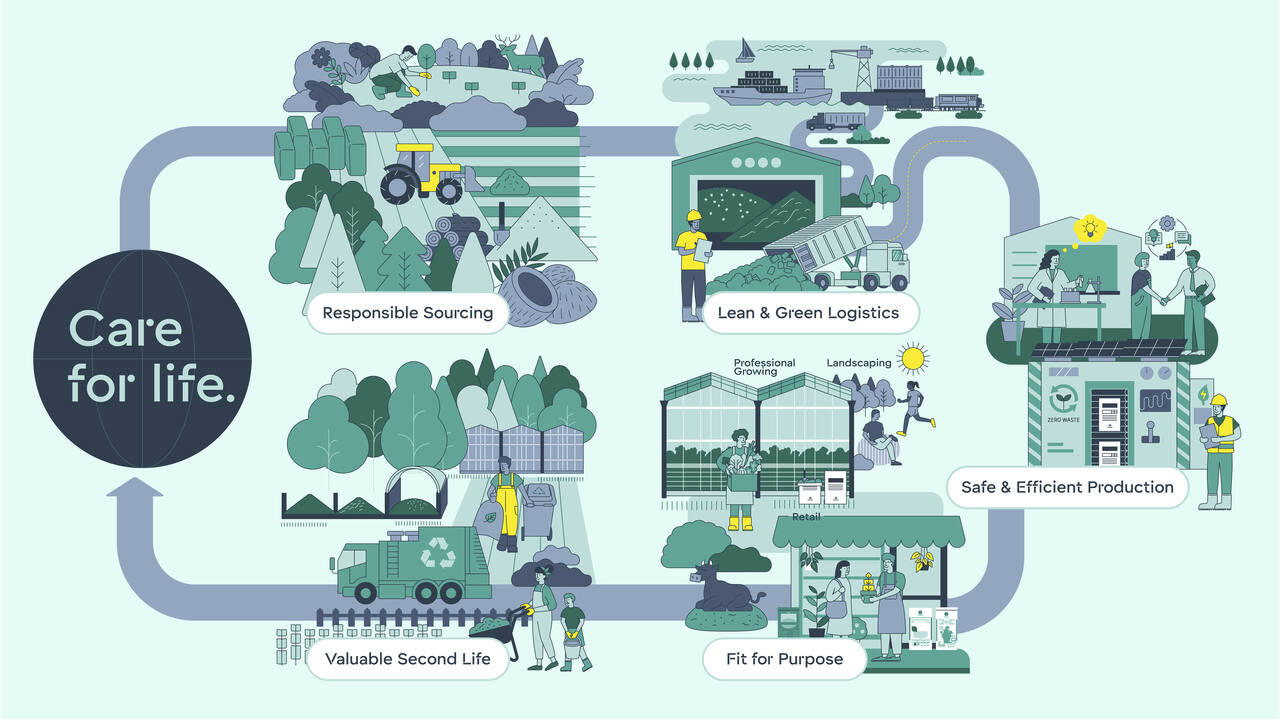

To answer this question, you need to look at the whole lifecycle from where materials in the growing medium are sourced, to how they are transported, to what is being done with them after use. Like is done in our Sustainability Compass, a transparent method of assessing each aspect involved in creating substrates to be used as growing media, from retail to raw materials in bulk. Using this method, we are able to create specific targets, identify areas for improvement, and recognize even small changes that can make a big difference.

What materials do we use?

When evaluating which materials go into our substrates we not only look at their unique characteristics such as water hold or air capacity, but we also take into consideration their environmental impacts.

Benefits |

Risks |

|

| + Possess excellent physical, chemical and biological properties for plant growth + Safe in many ways: no human pathogenes, no pesticides, very low plant pathogenens, no fertilization issues, good food safety + Usable for acidic plants + Peat is an extremely well understood, reliable and consistent option for many growers + Harvesting under very strict environmental regulations + Excellent availability |

– Low re-wetting capacity – Peatland growth is slow (~1 mm per year) |

|

| + Renewable material + Good structure and stability + It provides a favorable balance of air and water to plant root + High re-wetting capacity + Holds its structure well + Low bulk density |

– Treatment needed to prevent release of phytotoxic levels of salts – Cleaning and buffering is a water intensive process – Through processing, higher risk for phytosanitary and chemical pollution – Nitrate and other salts will come into the environment because of the buffering treatment |

|

| + Renewable material + High total porosity and air holding capacity after treatment + It is used to optimize the physical properties of other material components (e.g. reducing bulk density and increasing air space) |

– Need of fertilisers, especially nitrogen, is higher when using wood fiber – Rarely used as a stand-alone growing media component because it retains insufficient plant available water and has a tendency to become compressed |

|

| + Composts are high in nutrients + Composting allows for the re-use of many waste materials that would otherwise end up in landfill or incineration plants + Composts can support in pathogen suppression |

– High bulk density (70–85% of the consists of minerals) – High pH and nutrient levels (mainly potassium and phosphorus) – Requires other materials to operate (usually peat – Prone to contaminants |

|

| + Good structure for long period + Good drainage + It has a high air capacity + Excellent for epiphytes (e.g. orchids) |

– Very low water holding capacity – Secondary treatment needed to make sure no pine tree nematodes are transported – As a waste product its physical, chemical and biological properties can vary – Use in low amounts in mixture – Nutrients mainly potassium, sodium and chloride – Growth inhibition when used in high amount |

|

| + Excellent balance of humidity and airiness + Very low bulk density + Low pH and nutrient level (easy to adapt to the needs of different plants) + Very easily available water |

– Production capacity dependent on timely requests – New material, less experience |

|

| + High buffer capacity for nutrients + Good water storage + Facilitate faster rewetting |

|

– Compaction and waterlogging – Can be sticky when wet and tough when dry – High weight |

| + Ensures high air capacity and adds drainage + Structurally stable |

|

– Energy intensive production – Low water holding capacity |

| + Both virgin and used sand can be used + Allows quick draining + Adds weight and stability |

|

– Hard to irrigate – Very heavy |

| + It is clean, sterile, and resists compaction + Added to soilless mixes to improve drainage and aeration + Reusable, it doesn’t decompose |

|

– Energy intensive production – Non-renewable resource, made from volcanic rock – Low water holding capacity |

Peat in our growing media

Peat is a unique organic raw material, formed of partially decayed vegetation in wetlands. It’s classified as a slowly renewable biomass source (The Intergovernmental Panel on Climate Change – IPCC).

Why do we use it?

Peat is the safest, purest and most-used raw material for growing because it:

- Contains no weeds or pathogens

- Improves soil structure

- Increases water retention

- Helps to reduce leaching of nutrients

- Is highly tolerant of pH variations, so it improves soil buffering capacity

- Enables us to trial and use new circular and renewable materials

Sourcing

About 40% of the European peatland is used for agriculture and forestry. These peatlands are drained, otherwise they can’t be used.

When peatlands are drained and degraded, they emit CO2 (carbon dioxide).

These degraded peatlands can be used for peat production. Their rehabilitation afterwards turns them into carbon sinks, reducing CO2 emissions significantly.

About 58% of the peatlands in the EU are degraded.

*Sources: RPP. IPS 2010 Strategy for Responsible Peatland Management, IPS, 2010.

Responsibly Produced Peat

Responsibly Produced Peat certification ensures that peatland is

used, managed and restored in a responsible way.

Responsibly Produced Peat is an independent organisation that ensures:

- Pristine peatlands are untouched

- Peat production is as environmentally friendly as possible

- Peatlands are sustainably restored after production

- Best Available Technology (BAT) harvesting means smart production and clean waters.

By 2030 95% of Kekkilä-BVB peat will be RPP certified.

Future of growing media

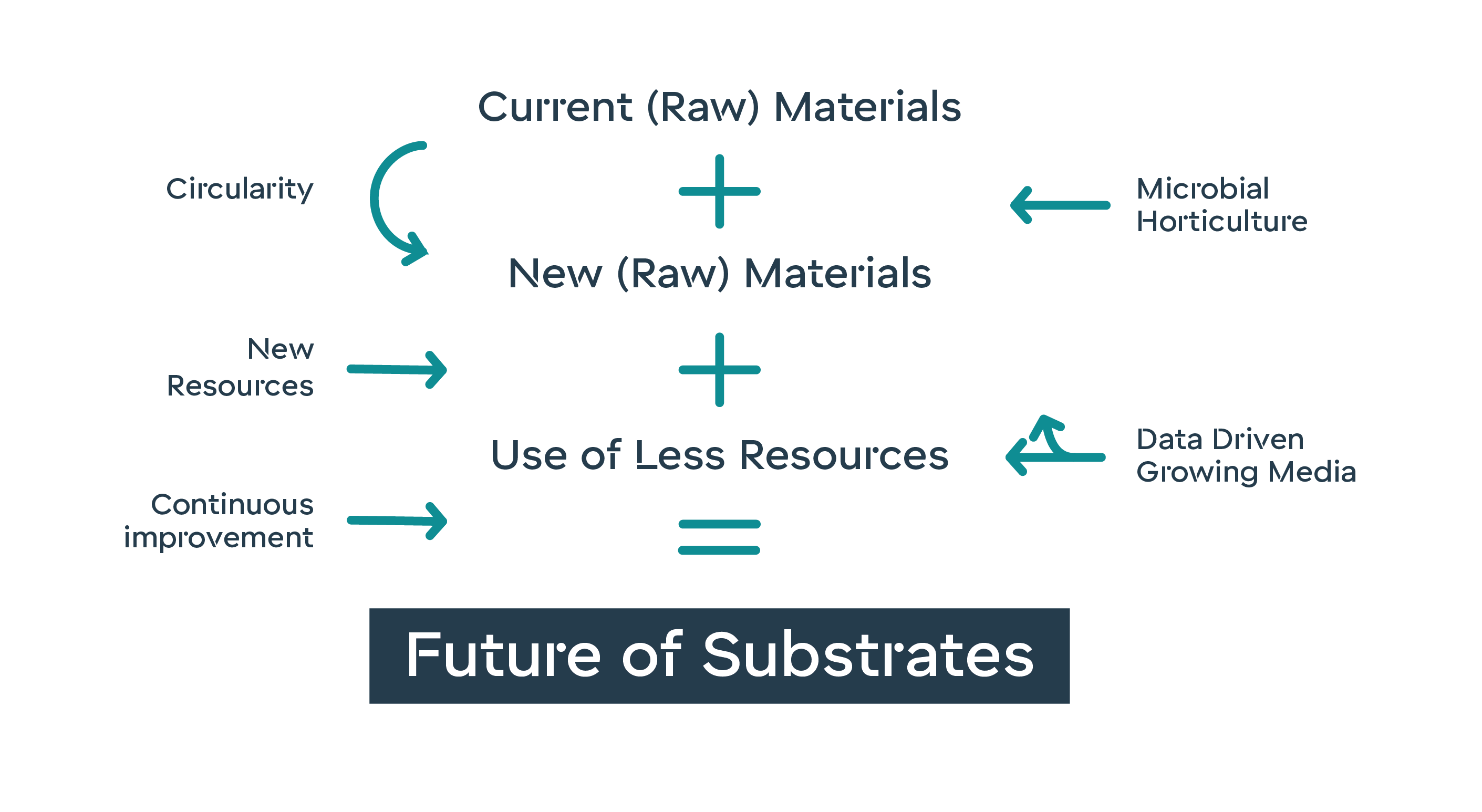

To meet the challenges of the 21st century, the amount of growing media will need to increase by 332% over the next 30 years*. At the same time, there will be less resources such as water, arable land, and various materials. In order to tackle this problem we do our internal research as well as collaborate with customers and research institutes to investigate and develop new ways of growing sustainably, by utilising and optimising our current materials throughout their lifecycle, as well as exploring potential new alternatives.

*Source: Growing media for food and quality of life in the period 2020-2050, Professor Chris Blok et al, Wageningen University & Research, 2020

Growing Media Community

If we want to secure a happy and healthy future for people and planet, then collaboration is essential. Our growing media community is not just made up of growers and innovation partners, but we also have to work along side our competitors so we can share knowledge to help the public and decision makers understand the world of horticulture.

Growing Media Europe

We are members of Growing Media Europe, an international NGO representing the producers of growing media and soil improvers at European level. We work alonside our customers and competitors to give a voice to European horticultural industry